The reducer jointly developed by maxma and a renowned European manufacturer can be equipped with 1-16m3 capacity mixing tanks and can achieve precise control within the 1-16rpm range of the mixing tank.

All the main components are imported in their original form. German original imported bearings and European original imported oil seals are adopted to ensure the reliable and durable quality of the reducer with an extremely low failure rate.

Product advantages

The reducer jointly developed by maxma and a renowned European manufacturer can be equipped with 1-16m3 capacity mixing tanks and can achieve precise control within the 1-16rpm range of the mixing tank.

All the main components are imported in their original form. German original imported bearings and European original imported oil seals are adopted to ensure the reliable and durable quality of the reducer with an extremely low failure rate.

The sun gear shaft and two-stage planetary gears are made of original imported materials from Germany. The tooth profile design is optimized and they are manufactured using the German vacuum quenching carbon furnace process. The overall operating noise of the reducer is extremely low.

Based on the hydraulic transmission reducer, it has been optimized and upgraded to adapt to the new generation of electric drive systems, while also meeting the adaptation requirements of traditional hydraulic motors. The oil-electricity connection is convenient for rescue in emergency situations.

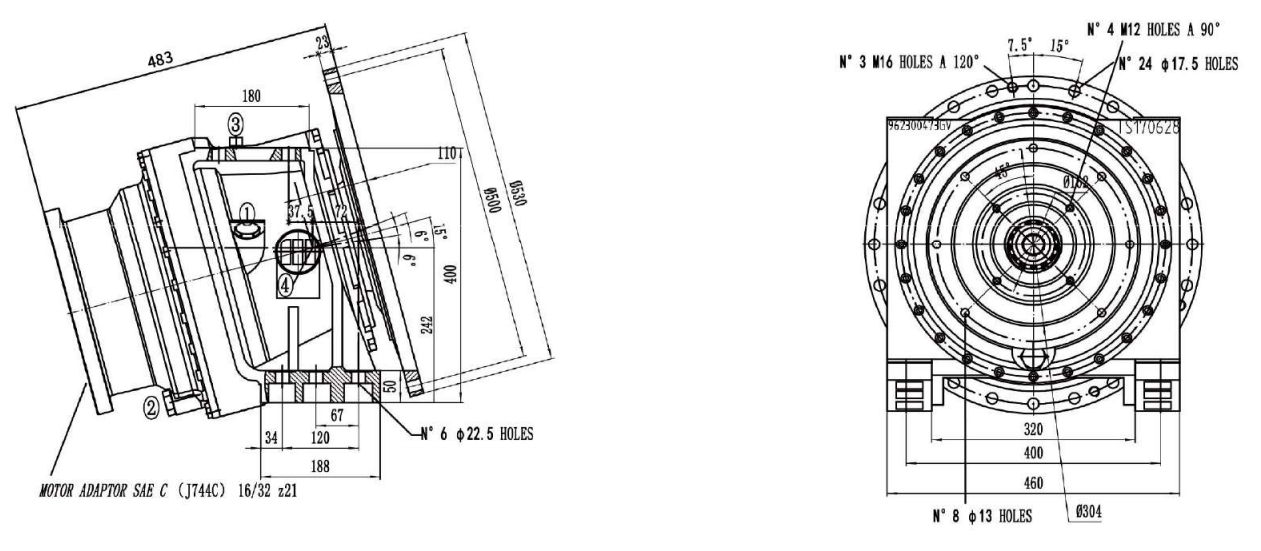

External dimensions

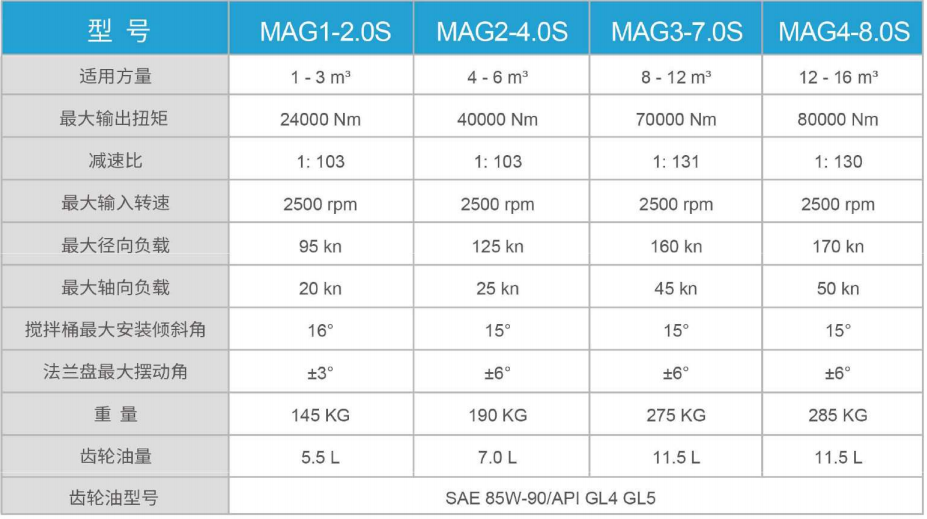

Technical Specification

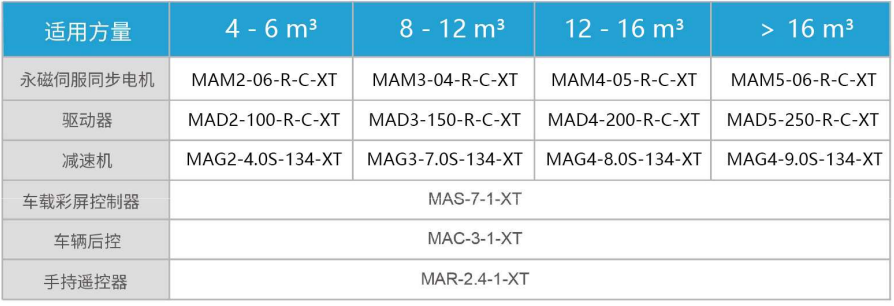

Selection and configuration

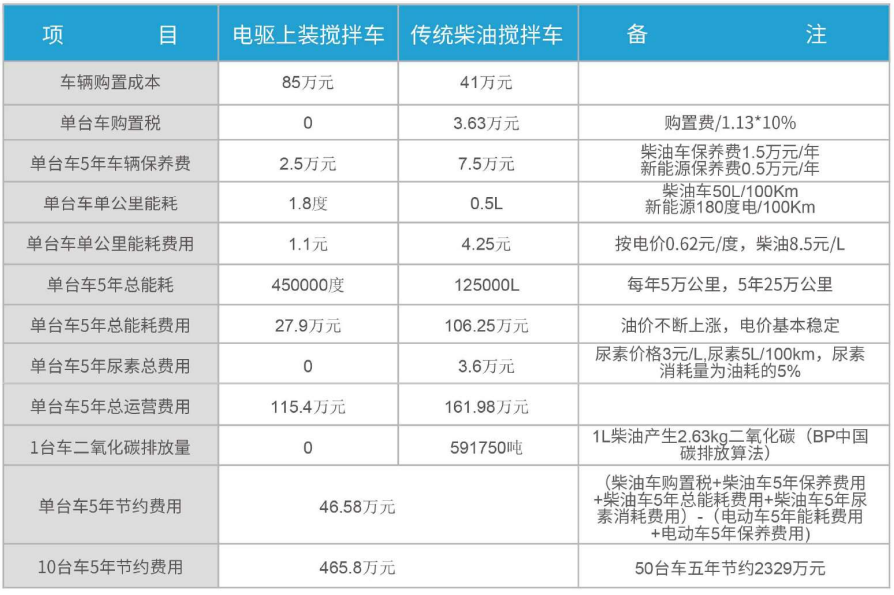

Economic comparison table of Oil/Electric Mixer Trucks

0574-87668083

18042069740